Latest fashions arrive via the Elbe

For its hinterland transport needs between Hamburg and Braunschweig, New Yorker relies on inland waterway craft and has fared well with these for years. ...

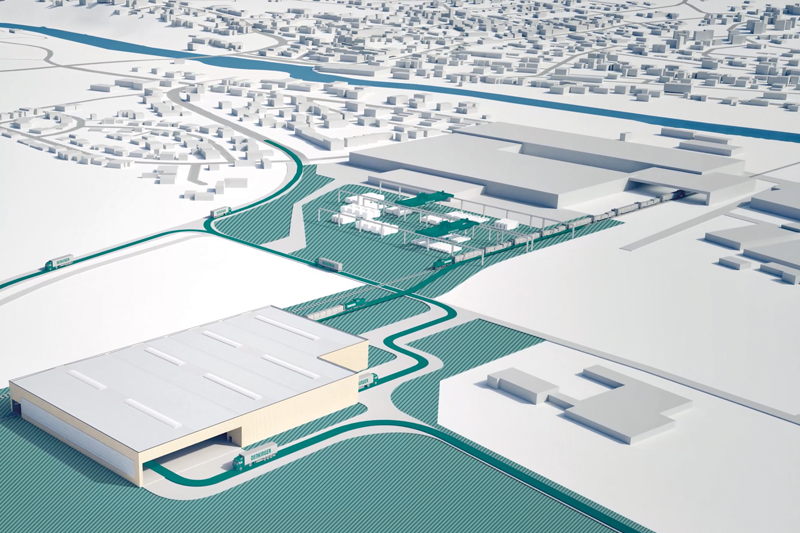

Within a very short time span, mid-sized Denkinger forwarders have developed a rail cargo terminal at Rottenacker in the Alb-Danube region. This is resulting in the emergence of 60,000 square metres of logistics space. “The new intermodal site is a building brick in our strategy to connect the southern hinterland and Northern Germany with our own facilities and rail sidings,” states the Denkinger CEO Simon Brunner, explaining the purpose of the new development.

When the industrial engineer began with the construction in 2021, he was looking at an abandoned industrial site with 1.5 kilometres of disused railway sidings. The speed with which commissioning has taken place positively surprised him: “Today, only 18 months later, Deutsche Bahn – German Rail comes to us five times per week: We have from five to twelve railcars being cleared per day.” Two installed crane tracks with four cranes handle transhipment between truck and train in the open areas: And, this is only the first of three development phases.

„Logistics areas

totalling

60.000 square meters

are beeing created."

The second stage is already very visible. An eleven- metre-high building easily attracts your attention. On the forecourt 100 tons of local larch wood are stacked. This will be used as cladding, except on one side, where a PV – photo-voltaic plant will be installed, which together with the PV units on the roof will achieve a peak performance of one megawatt. Glass fitted between the PV modules on the façade will provide a suffused interior light. Roughly 150 metres of rail track run right through the hall, where going forward, up to ten railcars can be cleared under cover by crane track and forklifts. Brunner is reckoning with completion in November 2023. From then on, sensitive heavylifts can move into the structure protected from wind and weather.

The third phase will be adjacent to the hall. Here, further handling and storage facilities right next to the rail siding will be constructed, universally suitable for heavy loads, raw materials, steel, precast concrete elements and containers. “It is our aim to develop as many areas next to the tracks as possible, since we tranship directly between rail and truck. To achieve the necessary agility, a final total of seven crane tracks will be available, supplemented by forklifts up to 16 tons and reach-stackers. With a view to the seaports, Brunner can also well imagine maintaining an empty-container depot in Rottenacker: “We fulfil all the requirements, possess all the handling equipment and have had container handling in our portfolio for years.”

The site’s short development time was something special for Brunner too. “We are already operating four rail-sidings, so we know that it can really take time until the first train shunts in. However, in Rottenacker everything fell into place. And even where that wasn’t the case, Brunner and his team were able to have a positive influence on the time-line. The 1.5 kms of track, including a bridge over the Danube, were in a reasonable condition and were quickly reactivated.

However, the points were no longer usable. Instead of waiting for DB Netz – German rail network, Denkinger accelerated the process. “We acquired the points, replacing the old ones within seven months. With that we were able to accelerate things,” reports Brunner. This ‘hands on’ mentality is in line with Denkinger’s company philosophy. The CEO is absolutely sure: “To remain competitive as a mid-sized company, we need to be lean with quick decision-making.” Thinking of the German economy generally, precisely this aspect bothers him. In this country, procedures are too slow, bureaucratic and lumbering. The company experiences this not only when it comes to developing rail-sidings, but also to licensing procedures for special and heavylift transport.

At the central logistics facility in Allmendingen, also located in Alb-Danube county, Denkinger equally intends to construct a rail cargo terminal following the Rottenacker blueprint. The required hall, through which the rail track should run, has been built for five years. “However, in this case, it’s a question of laying new tracks involving considerably greater coordination, examination and authorization procedures. Now the rail siding in Rottenacker has overtaken the one in Allmendingen,” adds Brunner with a grin.

The rail planning concept began with their own rail sidings 20 years ago at their headquarters in Ehingen, located only five kilometres from Allmendingen. Denkinger has maintained its own branch in Bremerhaven since 2020, where trucks and rail services can be handled. “We have good preconditions for establishing sustainable logistics concepts on the North-South axis. With a view to the seaports of Bremerhaven and Hamburg, going forward, we want to get the biggest railcar groups or even block trains off the ground,” stated forward-looking Brunner. He feels vindicated in his view, since his company’s investments in intermodal facilities have shifted many thousands of truck shipments annually onto rail.

Whereas for Denkinger, over long distances rail is preferred, trucking is needed for regional distribution. For the CO2-neutral transport chain, two power-driven 40-ton trucks have been deployed at the Rottenacker facility since February this year. Going forward, their batteries will be replenished via four quick-charging columns, preferably using in-house produced power from the PV facility. With the quiet, environment-friendly long-distance trucks Denkinger is one of the trailblazers in Baden-Württemberg, where up to now only a good ten power-driven 40-tonners have been registered. It was also very positive to see that one of the ‘Volvo FH electric’ truck was being driven by a woman. In total, Brunner plans to extend the e-truck fleet with ten more 40-tonners with a range of 300 kms each, to take over the needs-driven short distance deliveries. By his calculations that will really fit the bill.

Denkinger planners have IT support, when choosing whether to load on rail or truck. Their software, developed in-house, initially checks whether the freight to be loaded is suitable for rail or truck. As a second step, the program shows the optimal load compartment distribution for each mode of transport. This ensures that the suitable mode of transport, or a combination is implemented, deploying as few trucks or railcars as possible. Since, when you have taken all sustainability issues into account, at Denkinger decisions are based on entrepreneurial thinking. Brunner summarizes their maxims together: “We want to present shipments ecologically and economically.”

You can easily believe Brunner when he says: “We have an IT affinity and want to progress innovatively and open for technology.” Denkinger’s top management focuses its vision even further, when considering their strategic direction. The top trio, Nico and Peter Denkinger plus Simon Brunner are singing from the same hymn-sheet: “We want to develop into an IT company with its own logistics facilities, integrated into at least two modes of transport.”