CGH Cruise Gate Hamburg GmbH, Cruise Center Altona

Hamburg Cruise Center Altona lies on the Elbe between the Fish Market and the beach at Oevelgönne. The terminal's roof terrace opened in 2011 offers a…

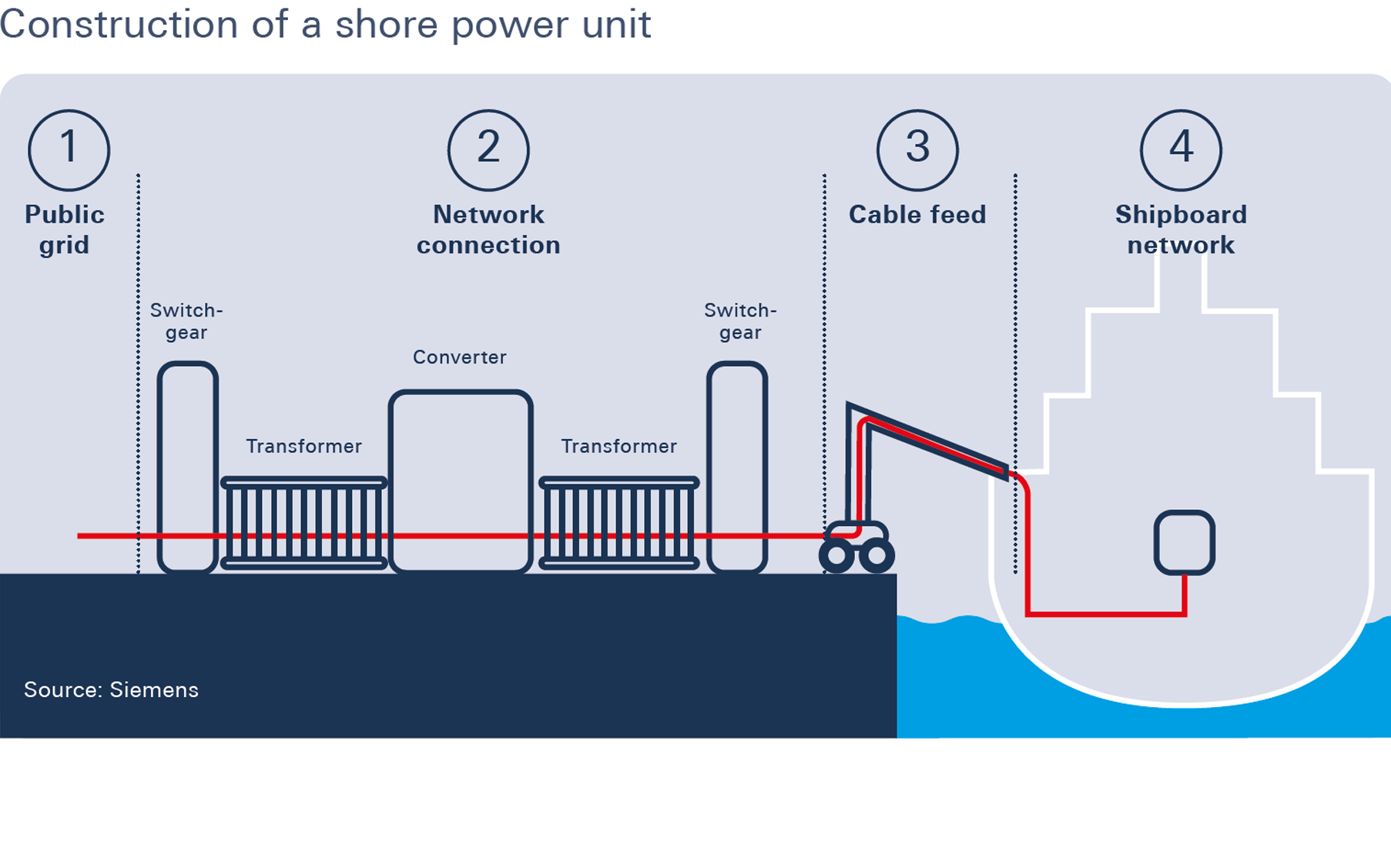

A mass of emissions have occurred during ships’ lay times because they have had to leave their diesel generators running. Shore-based power puts a stop to that. This involves linking the ship to a shore power unit on the quay. The vessel can then tap into power from the public network instead of producing it on board. Shipboard generators can be switched off. That reduces the emission of air pollutants such as nitrogen and sulphur oxide, fine particles and CO2. One positive side-effect is less of a din.

For Nikolay Sudarev, Deputy Project Manager Shore Power for HPA – Hamburg Port Authority, the beneficial effects on air quality and hence for the health of the urban population are a decisive argument for using shore power. The results are better than those for consumption of alternative fuels by internal combustion engines. “Looking at their respective environmental records, shore power is superior to LNG, synthetic fuels or biofuels. In burning these, pollutants continue to be emitted. By contrast, any shore power derived from renewable sources is virtually emission-free. Especially for ports close to cities, this technology is of special importance for people’s health and wellbeing.”

HPA – Hamburg Port Authority (HPA) Cruise Center Altona installed what was then Europe’s first shorebased power facility for cruise ships back in 2016. This has been in regular operation since 2018. With almost everything functioning automatically, only a few minutes elapse before power flows from shore to ship – and it’s derived exclusively from renewable sources. The unit is used primarily by the ‘AIDAsol’. Supply to additional ships has been hampered by the pandemic. Numerous shipping lines have postponed planned conversions. Yet Sudarev remains confident that shipping companies will again be putting more effort into addressing the topics of environmental compatibility and sustainability. The first new planned connection and integration tests are a good indication of this. In 2022 the ‘AIDAsol’ took shore power fifteen times. Additional calls with shore supply are planned by year-end. The ‘Europa 2’ has also regularly ordered supplies of shore power. Sudarev estimates that this year the facility will have enabled approximately 500 tons of CO2 to be eliminated.

In 2019 the government of Hamburg decided to expand the Port of Hamburg’s shore power facilities. Construction of these is planned at Steinwerder and HafenCity cruise terminals. In addition, seven connection points are to be built for containerships – three at CTB – Container Terminal Burchardkai, three at CTH – Eurogate Container Terminal Hamburg, and one at CTT – Container Terminal Tollerort. In 2024 the state of-the-art CTA – Container Terminal Altenwerder is also to be given a shore power facility. This will profit from experience with the first years in operation of the larger facilities. The cruise terminal shore power point in Steinwerder should be completed in 2023, followed by the one at HafenCity Terminal in 2024. Test operation at the container terminals and in Steinwerder should commence next year. From 2023, Hamburg will therefore be the first port in Europe to offer shore power supply to both cruise ships and large containerships. “This is an important step towards decarbonizing the port, putting Hamburg many years ahead of the EU’s scheduled regulation to reduce CO2 emissions in comparison with 1990 by at least 55 percent by 2030,” explains HPA’s CEO Friedrich Stuhrmann.

Terminals will each be equipped with a connection point from the public network, a transformer station, and the appropriate ship supply units, or even in front of, the quay wall. These facilities will be so constructed as to enable parallel supply to two vessels at each terminal. HPA analyses indicate that this is currently the optimal technical solution, which can be extended to meet growing demand. The port administration has ascertained in advance from Stromnetz Hamburg and other parties involved which cable, ducts and technical equipment will be required for ability to supply the maximum required performance and to guarantee reliable delivery.

With the provision of shore supply infrastructure being extremely capital-intensive in any case – HPA is investing around 95 million euros in the building projects – use of a generally applicable system makes sense in the long term. To facilitate access to this for as many users as possible, equipment is being built to international standards. HPA is cooperating closely there with other European ports, while also trying to prompt the relevant shipping companies to convert their fleets. While conversion may involve heavy costs, it is also an investment in the environment and the future. The more ports offer these facilities and the more intensively shipping lines use them, the quicker this will pay off.

Unlike everyday electricity consumption, integrating a ship involves not simply plugging it in, but a lengthy process. If power cuts are to be avoided, the first use of shore power, which often represents virgin territory for the technical experts on board, requires extremely cautious handling. To integrate a ship, several port calls are frequently required. Yet since ships mostly only remain alongside for a short time, this can be an obstacle. Since the units for containerships are novel and so far of a unique size and type, their forthcoming integration will be all the more challenging. Yet the good news is that once integration is achieved and a vessel has been successfully certified, shore power can be tapped at every subsequent call relatively rapidly and free of problems.

In parallel with building the units, HPA is canvassing for ships wanting to achieve integration as test candidates. Further discussions are currently in progress with such major European players as CMA-CGM and Hapag-Lloyd. Other lines to have expressed interest include several from Asia, Cosco, HMM, ONE and OOCL.

HPA’s plans for shore power in the Port of Hamburg envisage equipping that all significant berths by 2030 with infrastructure to meet requirements and achieving CO2-neutrality as quickly as possible. Stuhrmann is convinced that even if shore power involves challenges, it is very clearly the obvious way of making a contribution to greater sustainability and climate neutrality. To achieve the maximum possible environmental impact, the offer of shore power must be further extended in as many ports as possible. In Rotterdam and Antwerp-Zeebrugge, in particular, extremely strong potential exists for saving CO2 and avoiding pollutants. With support from Dr Peter Tschentscher, First Mayor of Hamburg, and his office, the Port of Hamburg plans an agreement with the Northern Range ports on speeding up equipment for shore power and boosting its use. To achieve a genuine breakthrough, however, it will be essential for the shipping industry, port management and politicians to close ranks.